A brief discussion on "amorphous motor"

Today we’re going to talk about a very cool

technology topic: amorphous motors. This research field has a history, and now

it seems that amorphous motors are expected to become the main material for

motor stator cores!

Amorphous alloy is also called "liquid

metal" or "metallic glass". This new type of soft magnetic

material mainly contains elements such as iron, silicon, and boron. The

production of amorphous alloy is through rapid cooling technology, which can

form an amorphous alloy thin strip with a thickness of about 0.03mm. This

material has the advantages of low coercivity, high magnetic permeability and

high resistivity, making it very suitable for power transmission in the medium

and low frequency fields.

At present, amorphous alloys are mainly used in

distribution transformers to replace traditional grain-oriented silicon steel.

Compared with oriented silicon steel, amorphous alloy is more energy-saving and

environmentally friendly, with a shorter manufacturing process and higher

efficiency. Moreover, it is also a green material that is recyclable throughout

its life cycle, which is both energy-saving and environmentally friendly.

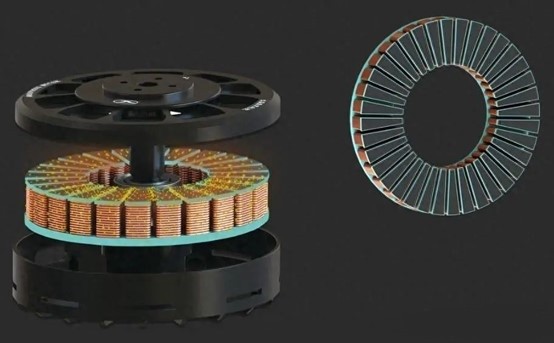

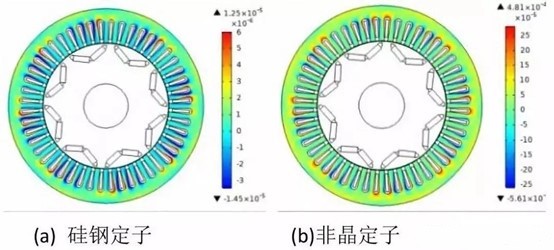

Now, scientists are considering using amorphous

alloys as motor stator core materials to manufacture amorphous motors. This is

of particular concern in the new energy vehicle industry. Compared with

traditional silicon steel sheets, amorphous alloys have high resistivity under

high-frequency conditions, which can effectively reduce eddy current losses and

thereby improve motor efficiency.

Research on amorphous motors has a long history.

From the amorphous alloy stator core patent applied for by General Electric

Company in the United States in 1978 to the various amorphous alloy motors

developed by Hitachi in Japan, this field has experienced rapid development.

Various institutions, including companies and universities, have conducted

intensive research in this area.

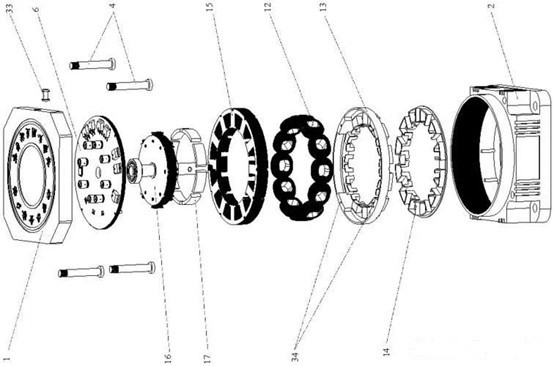

However, although the prototype of the amorphous

motor has been manufactured, mass production has not yet been achieved. The

thin, brittle, and hard characteristics of amorphous alloy materials make

traditional stamping processing methods difficult. However, with the continuous

advancement of technology, we have reason to believe that amorphous motors will

play a greater role in high-frequency motor applications in the future.

Summary: Amorphous motors will become a revolutionary technology, leading us into

a new era that is more energy-saving and efficient.