Application of Nanocrystalline Magnetic Rings in Bearing Corrosion Problems of 800V High-voltage Pla

Application of Nanocrystalline Magnetic Rings in Bearing Corrosion Problems of 800V High-voltage Pla

Yunlu New Energy Technology: Application of

Nanocrystalline Magnetic Rings in Bearing Corrosion Problems of 800V

High-voltage Platforms

Source from Gasgoo

In 2021, the industry began to raise the

issue of electric corrosion of electric drive bearings. With the trend of 800V

electric drive systems, this issue has become the industry’s focus.

What are the causes of bearing

electrical corrosion? On the 400V platform, it is mainly due to magnetic

imbalance and asymmetry. The bearing cuts the magnetic induction lines during

rotation to generate shaft voltage, and electrostatic induction generates shaft

voltage. The 800VSiC high-voltage platform will instantly generate higher du/dt

and di/dt when switching quickly, and a common-mode voltage will be generated

during the propagation process; when the motor speed is low or the bearing

temperature is high during long-term operation, the bearing lubrication and

Insufficient or reduced insulation performance will break down the bearing oil

film, destroy its insulation, and cause pitting corrosion in the bearing.

Regarding solutions to bearing

electrical corrosion, on December 14, 2023, at the 4th Automotive Electric

Drive and Key Technology Conference, Zhang Ge, R&D General Manager of

Qingdao Yunlu New Energy Technology Co., Ltd. proposed: Reduce or eliminate

bearing electrical corrosion The main method is to insulate the bearing,

rotating shaft or bearing chamber, guide the shaft current to the motor shell

in a directional manner and suppress the increase of the shaft voltage. The

main methods are "attenuation", "drainage" and

"blocking".

Zhang Ge said that the nanocrystal

magnetic ring uses the attenuation principle to consume the harmonics on the

three-phase side to reduce the shaft voltage. At the same time, Zhang Ge

systematically elaborated on the nanocrystal characteristics requirements,

shape selection, core loss calculation, production requirements, magnetic core

fixation methods, and magnetic ring reliability evaluation of the nanocrystal

magnetic ring.

The following is the summary of the speech:

Analysis on the Causes of Bearing Electrical

Corrosion

There are several solutions available

To reduce or eliminate bearing

electrical corrosion, the main means are to insulate the bearing, rotary pump

or bearing chamber, guide the shaft current to the motor shell and suppress the

increase of shaft voltage. The main methods are as follows: blocking, diversion

and reduction. Barrier methods avoid current cross-talk by insulating bearings

and related components, which can be achieved by making ceramic bearings or

adding coatings to the bearings. The grooming method uses carbon brushes or

grounding rings to release the voltage in the bearing through grounding.

Finally, the reduction method uses a filter magnetic ring to eliminate

harmonics, thereby reducing the bearing voltage.

|

serial number |

Way |

means |

|

1 |

Blocking |

Insulated rotating shaft, insulated

bearing chamber, insulated bearings (insulating coating, ceramic bearings) |

|

2 |

Drainage |

Grounding brush, grounding ring,

conductive bearing (conductive grease, conductive seal) |

|

3 |

Attenuation |

Magnetic ring (nanocrystalline) |

Each individual solution has its pros

and cons, and there are limitations to relying on any one method alone to solve

the problem of bearing corrosion. A more reliable and effective solution is to

use a combination of "reduction", "diversion" and

"blocking".

Applications of Nanocrystalline Magnetic

Rings

The nanocrystal magnetic ring is used to

consume most of the harmonics on the three-phase side to reduce the shaft

voltage. Why are nanocrystals used on the three-phase AC side?

1) The magnetic permeability of

nanocrystals is generally higher than that of ferrite in a wide frequency

range, and they have higher impedance under the same volume. 2) The saturation

magnetic density of nanocrystals is higher than that of ferrite. Choosing the

appropriate magnetic permeability can achieve stronger bias resistance; 3) The

Curie temperature of nanocrystals is 560°C, which is much higher than the Curie

temperature of ferrite. On the DC side, we usually do not consider the

temperature factor because its temperature rise is low. However, on the

three-phase AC side, due to the influence of harmonics, the core heats up

seriously. To reduce the volume of the magnetic ring, we want the temperature

rise to be as high as possible. The current temperature resistance point of

nanocrystals is about 560°C, while the temperature resistance of ferrite is

usually 150°C or lower.

However, considering that the

temperature resistance of the plastic containing the nanocrystalline magnetic

core is limited to below 180°C, the main bottleneck we face is not the magnetic

ring itself, but the temperature resistance of the plastic. Major manufacturers

are working hard to increase the maximum temperature of three-phase magnetic

rings to about 180°C to reduce product volume.

Next, let’s discuss the characteristic

requirements of nanocrystals. The harmonics on the three-phase AC side are very

large, causing the magnetic core to easily saturate. This requires nanocrystals

to have certain anti-saturation capabilities and broadband characteristics. In

addition, the thinner the strip, the better the high-frequency properties of

the nanocrystals and the lower the losses. At present, the 14um ultra-thin

nanocrystalline magnetic core reaches higher impedance at 500kHz and 30MHz, and

is more suitable for applications on the three-phase AC side.

The anti-saturation capability of the

magnetic core can be improved by reducing the magnetic permeability, which can

be achieved by adjusting the composition of the strip and the heat treatment

process. At present, the commonly used magnetic permeability of three-phase

magnetic rings is about 60,000-80,000, but when the shaft current is too large,

the core temperature will rise, which may cause the plastic shell to burn and

melt. Therefore, it is necessary to improve the anti-saturation capability of

the magnetic core and reduce the magnetic permeability. Yunlu has been able to

reduce the magnetic permeability to less than 10,000 and is researching

low-cost mass-production technology.

Regarding the 14 micron ultra-thin tape

and 18 micron conventional tape, the thinner the tape, the better the

high-frequency impedance characteristics are. The development of 14-micron

strips originally originated from the heavy ion accelerator project built by

the country in Huizhou, Guangzhou, which has very high requirements for

high-frequency impedance. In the field of new energy vehicles, we also found

the need to develop in the direction of high-frequency impedance, so we applied

this technology to the electric drive three-phase magnetic ring. Test results

show that under the same size, the impedance of 14-micron tape can be increased

by 30% compared with 18-micron tape, and the volume can be reduced by 20%-30%

under the same performance.

Regarding the shape of nanocrystals.

Nanocrystals are wound from ribbons and are therefore sensitive to stress. To

maintain stable performance, stress needs to be minimized during the

manufacturing process.

Currently, the ring shape is the least

stressed during the manufacturing process, followed by the racetrack shape, and

finally the rectangular shape. In the case of the same volume, length, and

cross-section, the difference between the three shapes of magnetic rings is

about 5%. However, despite its superior performance, the ring is not commonly

used in the industry due to its insufficient space utilization. The runway

shape is widely used due to its better performance in small spaces.

In addition to shape, the length of the

magnetic ring is also a key factor affecting performance. In the case of the

same volume, the shorter the magnetic circuit length, the smaller the overall

impedance, and the higher the performance. To achieve this goal, we design the

magnetic circuit length of the product to be as short as possible.

Among the above factors, the temperature

rise problem is still the main factor limiting the performance of the magnetic

ring. To solve this problem, we consider using simulation technology to predict

temperature rise. Currently, the decomposition method is commonly used in the

industry to calculate core loss, but this method may not be accurate in complex

electric drive models.

To improve accuracy, we have launched a

project in cooperation with Tsinghua University. We plan to establish a loss

calculation model or method suitable for electric drive operating conditions

through large amounts of data collection and experiments, so that we can more

accurately predict temperature rise through simulation.

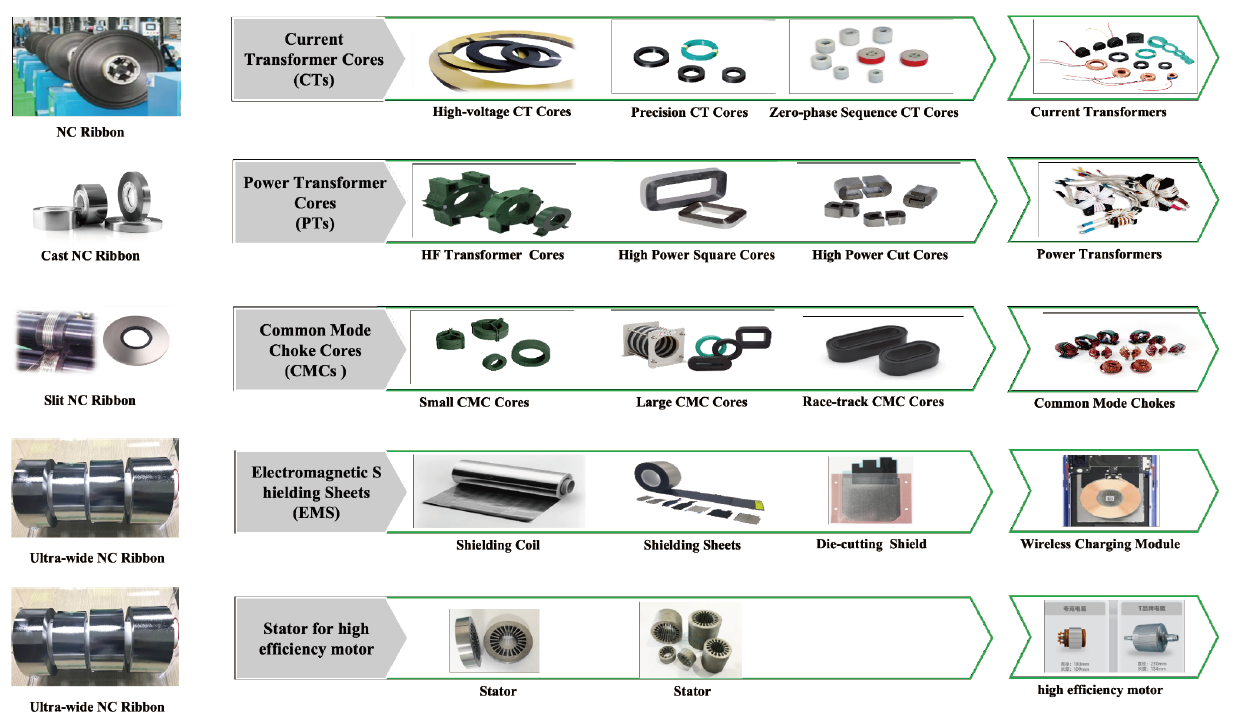

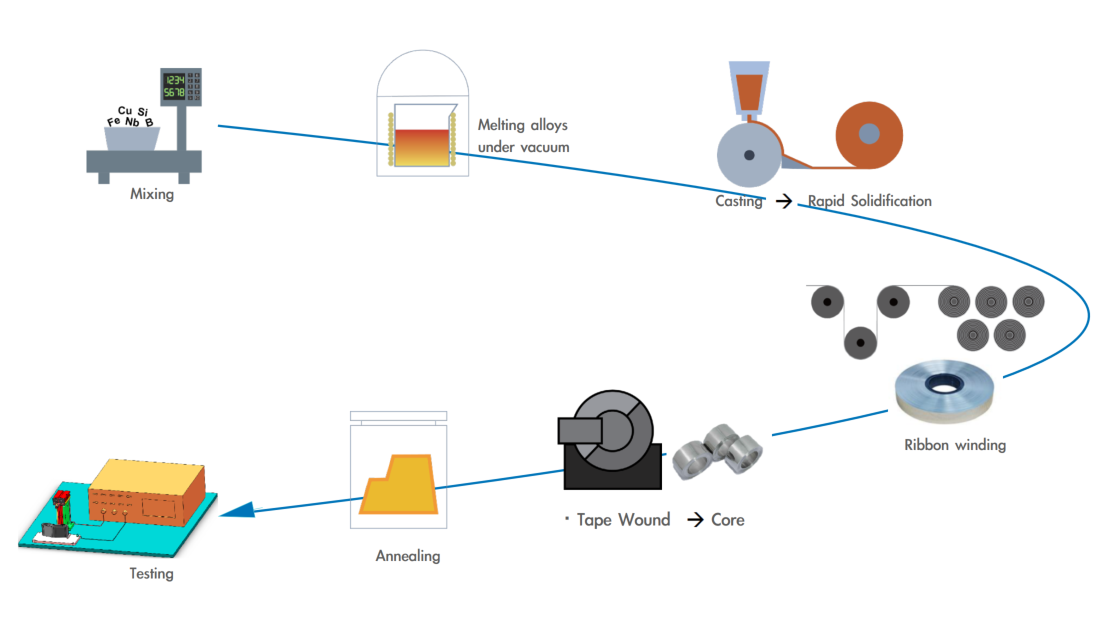

In terms of production, magnetic rings

are wound from strips. Initially, we produce the world's widest strips, which

are then cut and rolled as needed. Currently, we are studying automated

production. Since the usage in the automotive industry is relatively small, sometimes

manual production with auxiliary tooling may be more economical. In order to

ensure the performance and characteristic stability of the magnetic core, the

industry generally adopts curing method. Although curing is detrimental to core

performance, it ensures the cleanliness of the nanocrystals and the stability

of their properties.

In response to the needs of the new

energy vehicles and optical storage component industries, we have established a

3,000 square meter strip and magnetic core production line. The current market

competition is very fierce, and both cost and space are required to reach the

limit. Therefore, we have put forward higher requirements for parts and

components. We established the pilot center to meet the current market needs

and be able to quickly prototype and develop products that meet customer

requirements.

In original models, the problem of

bearing corrosion was often not considered and no corresponding space was

reserved. The initial method adopted by a certain car company was to create a

small space for connection between the motor and the electric drive. There are

currently three main fixing methods, among which the method of mounting on the

electric drive board is less used because it is not conducive to the

standardized control of the electric drive board. Since each car model and even

different platforms have different filtering requirements, the three-phase

magnetic rings are currently non-standard designs. To standardize the electric

drive board, the magnetic ring is mainly fixed between the electric drive shell

or the electric drive board and the motor.

At present, there are two main ways to

fix the magnetic core: glue fixation and potting. Relatively speaking,

dispensing is more recommended. Its process is simple, low cost, and the stress

squeeze on the nanocrystals is small, resulting in a small degree of

attenuation before and after assembly. However, in some oil mist environments,

nanocrystals need to be sealed, and potting is required. Welding is also used

in the industry, but there are risks. High vibrations and alternating hot and

cold conditions can cause welds to crack. Once cracked, causing the seal to be

broken, oil may enter the shell and mix with nanocrystalline debris, bringing

the debris into the motor environment, causing insulation problems. Considering

the oily environment, potting is the more common method.

However, a major difficulty currently

facing potting is stress, which may cause core degradation. To this end, Yunlu

has conducted a lot of research. Initially, many companies used normal pressure

potting without vacuuming, and the surface and performance tests seemed normal,

and the core performance even showed no attenuation. However during long-term

impact and high-temperature aging tests, problems began to appear. There will

be bubbles sealed under normal pressure potting. These bubbles will collide

under impact and high temperature, resulting in changes in the performance of

the magnetic core and the expansion of the plastic case.

Vacuum potting is widely used in other

industries, but in the case of nanocrystals, simple vacuum processing can cause

huge stresses on the core. If the glue flows into the middle of the magnetic

core, it will cause a huge change in its performance. After research, we

developed a stepped vacuum injection method.

To solve this problem, we started from

two aspects: one is to enhance the anti-extrusion ability of the magnetic core;

the other is to adjust the composition and process. We have passed the

reliability test on a certain car company's platform. At present, it can

complete high-temperature tests for about 1,500 hours at a high temperature of

180°C.

In addition, regarding the future

research direction of nanocrystals, we are working on improving the 100K high

magnetic permeability. Currently, there is a contradiction between the high

magnetic permeability of nanocrystalline ribbons at 100K and the low magnetic

permeability of 30K. Customers expect both to perform at a high level. However,

the current industry reaches a magnetic permeability of about 40,000 at 100K,

which is still far from the customer demand of 55,000. To this end, we have

launched relevant research projects.

High impedance and anti-saturation

capability at high frequencies are also the direction we continue to pursue. In

addition, high stress resistance is our main research goal in the future.

Currently, we are conducting relevant research and have achieved some results.

If the properties of nanocrystals can remain unchanged after being stressed, it

will greatly simplify the subsequent process. In the future, it is possible

that nanocrystals can be directly solidified and injection molded directly,

thereby saving space and simplifying the production process.