How to Extend the service life of motor rolling bearings

Before the first occurrence of fatigue pitting of the material of one ring or rolling element of the motor bearing, the number of revolutions of one ring relative to the other ring is called the life of the bearing. A group of bearings of the same model running under the same conditions, of which 10% of the bearings fail and 90% of the life that can be achieved when there is no failure (106 units), known as the basic rated life of the bearing. In addition to the basic rating life of the bearing is related to the load (the greater the load, the shorter the basic rating life, and the longer it is), and it is also closely related to the working environment and other factors. This article discusses how to extend the service life of the bearing from another angle.

The modern material relationship should have seven conditions, among which "supply and demand agree on the quantity, variety, specification, quality, model, etc. of the material supply"; "clear price, settlement method and method of bearing the cost of supply process"; As well as the three conditions of "binding supply contract", most people often ignore the relationship between these three conditions.

As we all know, the relationship between price and quality can be said to determine the price-performance ratio of the product, and the quality of the product can also be constrained by the price condition. This can be established by both parties. The quality of quality directly affects the company's production capital costs, expenses, profits and other indicators. In short, only the correct handling of the price-quality-cost relationship is an important channel for companies to reduce costs and increase profits.

Correct management is the basis of bearing service life

The technical operations of the material warehouse can be divided into three parts: storage acceptance, storage and maintenance, outbound shipment and distribution. Due to the wide variety of bearings (only Hebei Luoyang Bearing Factory has nine categories and more than 6,000 varieties), each plant has different security inspection methods, and every link such as long-distance transportation of goods may cause damage, so it must be carried out when the material is put into storage The inspection and acceptance of quantity and quality can only be put into storage if they pass the inspection (including relevant data, etc.). The storage and maintenance of materials is the central task of the material warehouse. No matter how good the material is, it can become a defective or waste product only if it is "managed" and not "maintained". Therefore, strict control of the warehouse temperature and humidity, and regular inspection of the bearing status is essential .

Correct selection, installation and use are the key to extending the service life of bearings

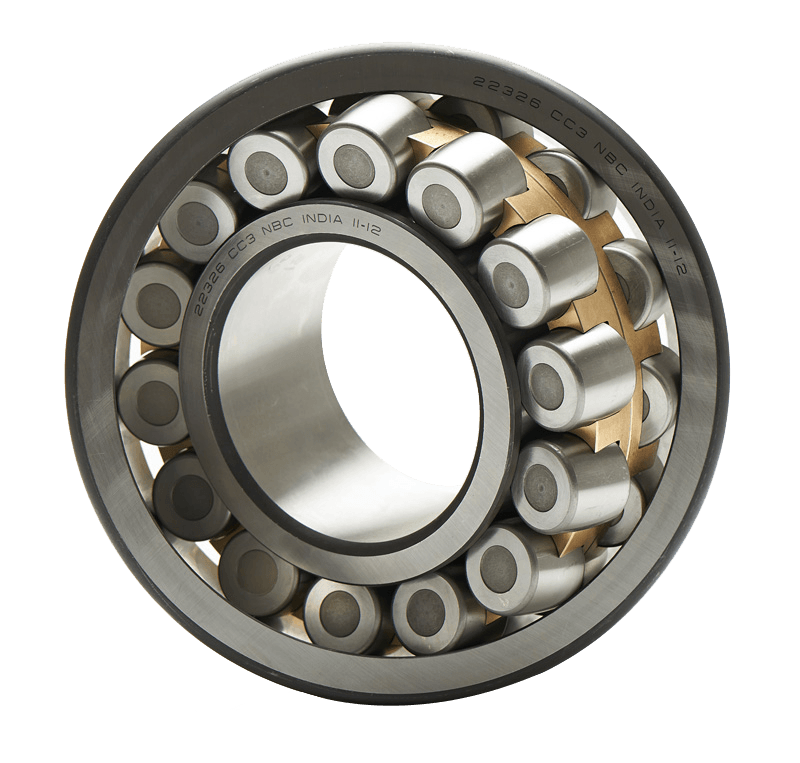

Correct selection is a prerequisite. There are many types of bearings, such as tapered roller bearings, self-aligning ball bearings, thrust ball bearings, self-aligning roller bearings, cylindrical roller bearings, etc. The same type of bearings due to different manufacturing materials (to retainer As an example, there are common steel plates, brass, bakelite, nylon, etc.), the same bearing is installed on different equipment (due to different cooperation), the same equipment in different external environments (different temperature and pressure), etc., above Various factors can generally be considered, but in a special operating environment or equipment operation, selecting the bearing model is not easy.

The correct installation method will also be one of the factors that affect bearing life. Different bearing models also determine different installation methods, and the use of auxiliary equipment is also different.

The installation method should be appropriate: when a factory repairs a linear vibrating screen, when replacing the double-row radial roller bearings (the bearing and the shaft are interference fit), because the employee adopts the single-row deep groove ball bearing installation method, it is simply The outer ring and the inner ring are driven in, resulting in the inner ring not being in place (with a difference of 0.15mm), and the inner ring and the bearing end surface are different from each other, resulting in a failure to start after assembly.

The correct installation method:

(1) When disassembling the bearing, use the depth gauge to measure the relevant data of the inner and outer ring positions;

(2) Use oil cooking to install the inner ring in place during installation (it needs to be measured with a depth gauge while hot until it is installed to a standard position);

(3) Since the shaft diameter is nearly 200mm, it is necessary to make self-made auxiliary tools and hydraulic jacks to assemble the bearings in place;

(4) Manufacturing method of auxiliary tools: Use a round steel plate (outer diameter is slightly smaller than the outer diameter of the bearing outer ring, inner diameter is slightly larger than the inner diameter of the bearing inner ring), weld a section of welded pipe (inner diameter is slightly larger than the shaft diameter, length Slightly longer than the distance from the bearing position to the end surface of the shaft), a steel plate (forced surface) is welded to the outer end of the tube.

When installing and using bearings, it is necessary to consider the changes between bearing components before and after installation, especially the changes in bearing clearance. Due to the friction between the rolling element and the raceway, the temperature of the bearing ring is higher than the temperature of the adjacent parts, so that the inner ring of the bearing expands and the fit with the shaft becomes loose (commonly called the outer jacket), while the outer ring of the bearing is The fit of the bearing seat is tightened, which causes the change of the working clearance of the bearing, which affects the rotation accuracy and bearing capacity of the bearing, and destroys the normal lubrication conditions of the bearing. Correct installation of clearance will help the normal operation of rolling bearings. Excessive clearance, large equipment vibration, and rolling bearing noise If the clearance is too small, the temperature of the rolling bearing will increase and it will not work properly, so that the rolling element will be stuck, which will seriously affect the life of the bearing.

The installation and use of bearings are the most important ones for the lubrication of bearings. In order to prevent the contact between the rolling elements, the ring raceway and the cage and the metal in the bearing as much as possible, reduce friction and damage, and prevent burns and corrosion, the rolling bearing must be lubricated.

The correct choice of rolling bearing lubricants should consider factors such as operating temperature, bearing load, bearing speed, working environment, etc. The operating temperature of the bearing is the deciding factor in selecting lubricants. Different lubricants are suitable for different temperatures, so first, you should choose a lubricant with a suitable viscosity according to the working temperature of the bearing. It is usually expected that the viscosity of the lubricant should not be less than 13mm2/s for ball bearings at different temperatures. For roller bearings It should not be less than 20mm2/s. Second, the bearing speed is also an important factor. The higher the rolling bearing speed, the greater the friction and heat generation caused by the movement of the ring, rolling element and cage. Generally, the temperature rise of a bearing is directly proportional to the product of the bearing inner diameter and the speed. The following table lists the allowable dn values for various types of bearings under different lubricants and lubrication methods.

From this, we can determine the suitable lubricants and lubrication methods for rolling bearings. Furthermore, the environment is also very important. If the air around the rolling bearing is humid, dusty, and the sealing device is simple, calcium-based grease that is not easily soluble in water should be selected. If the surrounding air of the bearing is dry and the moisture is less, sodium-based grease can be used.

Grease lubrication is not easy to be lost, so it is easy to seal and maintain, and it can run for a long time after being filled with grease at one time. However, the amount of grease filled in the rolling bearing should not be too much. According to experience, it is appropriate to fill up 1/3 to 1/2 of the space of the bearing and bearing housing. It should be filled to 1/3 or less at high speed. When the speed is very low and the sealing requirements are strict, it can fill the housing space.

Timely and correct maintenance is the guarantee for the extension of bearing service life

Maintenance of equipment is an important part of ensuring the normal operation of production. Bearings have a decisive relationship in equipment. How to maintain the bearings correctly is a very deep knowledge. The key lies in the change of concept, that is, to change the after-sales maintenance into the pre-maintenance maintenance. When the bearings are damaged due to lack of oil, grease, etc., the bearings are replaced, which will affect production.

In addition, establishing a maintenance system for post workers, maintenance workers, and mine (factory) maintenance supervisors to perform predictive maintenance, strive to reduce after-sales maintenance, and ensure the normal operation of equipment is another effective way to extend bearing life.

Conclusion

In short, there are many factors that affect the life of the bearing, here only from the human factor. Only everyone understands the equipment, everyone loves the equipment, and permeates the equipment maintenance and repair consciousness to everyone, so as to extend the service life of the bearing, improve the equipment operation rate, and ensure the normal operation of production.