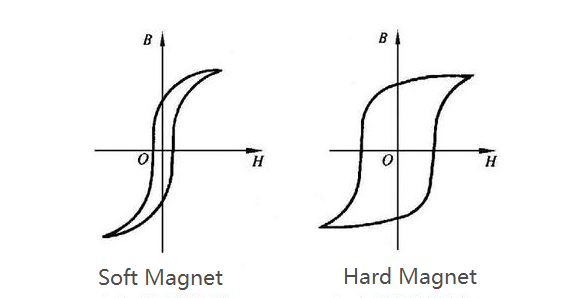

Hard and Soft

Materials that responds to a magnetic field in a certain way are called magnetic materials. According to their magnetic strength in the external magnetic field, materials can be classified as five types, which are diamagnetic material, paramagnetic material, ferromagnetic material, anti-ferromagnetic material, and ferrimagnetic material. Most materials are diamagnetic or paramagnetic, and they respond weakly to external magnetic fields. Ferromagnetic materials and ferrimagnetic materials are strong magnetic materials, and generally magnetic materials refer to strong magnetic materials. For magnetic materials, the magnetization curve and hysteresis loop are characteristic curves that reflect their basic magnetic properties. Ferromagnetic materials are generally Fe, Co, Ni elements and their alloys, rare earth elements and their alloys, and some Mn compounds. Magnetic materials are generally classified as soft magnetic materials and hard magnetic materials according to the degree of difficulty of their magnetization.

The softness or hardness of magnetic materials does not indicate the mechanical properties, but magnetic properties. Hard magnetic materials refer to magnetic materials that can retain its strong magnetism (referred to as magnetism) for a long time after being magnetized by an external magnetic field, and it is characterized by high coercivity. The soft magnetic materials are magnetic materials with very low coercive force, which are easy to magnetize and demagnetize when applying a magnetic field. Demagnetization means to weaken the magnetism by applying an opposite magnetic field after magnetic material is magnetized.

Permanent magnetic materials are the first hard magnetic materials discovered and used. The earliest compass invented in China (called Sinan) was made of magnetite, a natural permanent magnet. In 1931, the FeNiAl alloy came out with a maximum magnetic energy product (BH) of 40-80kJ/m³, which has been dominant in the 1950s and 1960s. In the 1960s, a new type of permanent magnet material has risen rapidly; that is, the rare earth permanent magnet material. In 1983, Japan announced that a high-performance NdFeB alloy with a maximum magnetic energy product of up to 303KJ/m³ is made through the use of traditional powder-sintering technology.

(1) High magnetic permeability: High magnetic induction intensity can be obtained under the weak external magnetic field, and it will reach saturation quickly with the enhancement of the external magnetic field.

(2) Low coercivity: when the external magnetic field is removed, its magnetic properties disappear immediately

(3) High saturation magnetic flux density (bs) and high saturation magnetization (ms). In this way, it is easier to obtain high magnetic permeability (μ) and low coercive force (hc), which can also increase the magnetic energy density;

(4) Low loss in magnetism and electric. This requires low coercivity (hc) and high resistivity.

The Common Hard Magnetic Materials

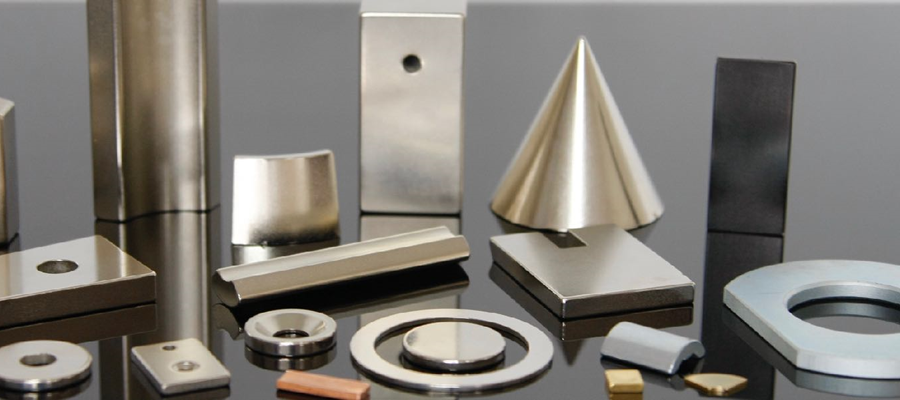

(1) Rare earth magnetic materials

Rare earth magnetic materials, which are a large class of permanent magnet materials with the highest magnetic energy product at present, are intermetallic (also called intermetallic compounds) with rare earth elements and iron elements as the main components. The NdFeB rare earth alloy developed and produced in China is permanent magnetic material.

(2) Metal permanent magnet materials

Metal permanent magnet materials are a large class of alloy permanent magnetic materials that have been developed and applied earlier.

They are composed of iron and iron group elements such as nickel, cobalt, and etc. Alnico and Fecrco are two major types of permanent

magnet alloys. The permanent magnetic performance and cost of AlNiCo alloys are medium, and they were developed relatively early.

Their performances vary with the chemical composition and manufacturing process, so their applications vary as well. Fe-Cr-Co-based

permanent magnetic alloys are characterized by medium permanent magnetic properties, but their mechanical properties can be applied

with various mechanical processing and cold or hot plastic modelling, and can be made into tubular, sheet, or linear shapes for a variety

of special applications.

(3) Ferrite permanent magnet materials

With fe2o3 as the main component, ferrite permanent magnet materials, which are composite oxide ferromagnetic materials

(narrow sense) and magnetically ordered materials such as anti-ferromagnetic materials (broad sense). Ferrite permanent magnet

materials are characterized by high resistivity, which is particularly beneficial for high-frequency and microwave use. For example, barium

ferrite (bafe12o19) and strontium ferrite (srfe12o19) are used widely.

In addition to the aforementioned three types of permanent magnet materials, there are some other permanent magnetic materials with

their unique characteristics in manufacturing, magnetism and application. For example, micro-powder permanent magnetic materials,

nano permanent magnet materials, plastic permanent magnet materials (used at the edge of refrigerator doors), processable permanent

magnet materials, and etc.

Soft Magnet

Soft magnetic materials, mainly refer to those magnetic materials that can be magnetized repeatedly and demagnetized after the external magnetic field is removed. When the magnetization occurs at Hc not greater than 1000A/m, such materials are called soft magnetic materials. For typical soft magnetic materials, the maximum magnetization can be achieved with the minimum external magnetic field. Soft magnetic materials can be magnetized and demagnetized, and are widely used in motor and electronic equipment. The most widely used soft magnetic materials are iron-silicon alloys (silicon steel sheets) and various soft ferrites.

Main Characteristics of Hard Magnetic Materials:

(1) High magnetic permeability: High magnetic induction intensity can be obtained under the weak external magnetic field, and it will reach saturation quickly with the enhancement of the external magnetic field.

(2) Low coercivity: when the external magnetic field is removed, its magnetic properties disappear immediately

(3) High saturation magnetic flux density (bs) and high saturation magnetization (ms). In this way, it is easier to obtain high magnetic permeability (μ) and low coercive force (hc), which can also increase the magnetic energy density;

(4) Low loss in magnetism and electric. This requires low coercivity (hc) and high resistivity;

The Common Hard Magnetic Materials

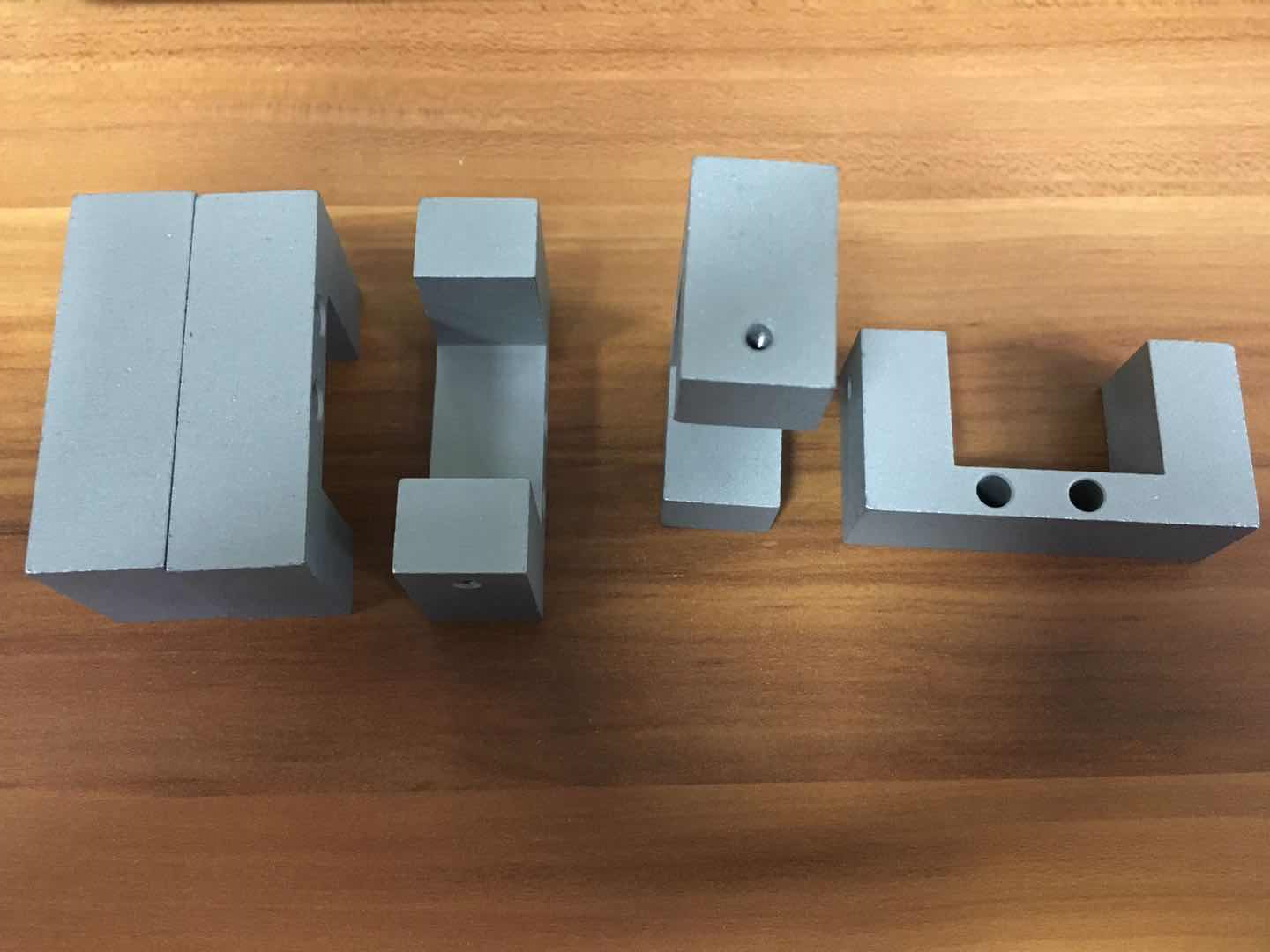

(1) Iron-silicon (Fe-Si) soft magnetic material

It is often called silicon steel sheet, is a magnetic material widely used in the motor industry. The reduction of magnetism and electrical loss p has been progressing with time. The type of magnetic materials include non-oriented Fe-Si alloy (i), single-oriented Fe-Si alloy (ⅱ), dual-oriented Fe-Si alloy (ⅲ), specially-treated Fe-Si alloy (ⅳ) and amorphous Fe-Si-B alloys of this magnetic material system.

It is a soft magnetic material with good performance and low permeability (μ) and coercivity (Hc), and it have high plasticity and are more

sensitive to stress. It can be used as pulse transformer materials, inductor cores and functional magnetic materials.

(3) Ferrite soft magnetic material

It has an outstanding advantage of extremely high resistivity, making it useable at high and ultra-high frequencies. The important material has been used in communication and a variety of electronic devices.

(4) Amorphous and nano-crystalline soft magnetic materials

Amorphous soft magnetic materials and nano-crystalline soft magnetic materials are the newest soft magnetic materials, which were developed in the late 20th century. Amorphous soft magnetic materials are characterized by its simple manufacturing process, wide range of chemical composition, uniform magnetic properties, and good isotropy (due to no crystal grain structure). After proper heat treatment of the amorphous soft magnetic material of the appropriate composition, the amorphous state can be transformed into a crystalline soft magnetic material with a crystal grain diameter of nanometers, a good soft magnetic material as well.

(5) Other soft magnetic materials

Choosing proper chemical composition and manufacturing process, soft magnetic materials with specific soft magnetic properties can be obtained. For example, iron-cobalt (Fe-Co) soft magnetic alloys with high energy and magnetization, iron-aluminum (Fe-Al) soft magnetic alloys with higher resistivity, Iron-silicon-aluminum (Fe-Si-Al) magnetocrystalline anisotropy and magnetostriction of almost zero, and etc.