A brief introduction of magnet

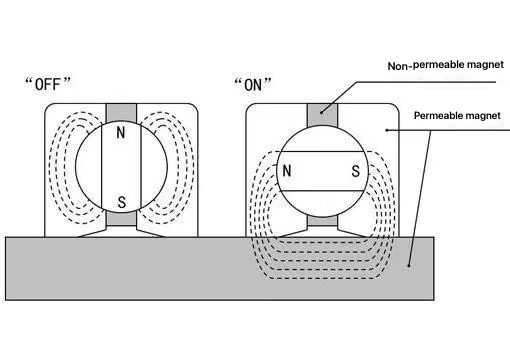

Conductor magnets are also known as magnetic flux field concentrators or cores. It is a laminate or block element made of magnetic material.

In the past, for medium frequency conductive magnets, it was used to using silicon sheet laminates or pure iron sheet laminates. In order to reduce iron loss, the thickness of the silicon steel sheet is reduced with the increase of frequency, and in theory the thickness of the silicon steel sheet should be less than its current penetration depth. For example, the medium frequency conductive magnet, when f-8 to 10kHz, choose 0.2 to 0.35mm thick. Due to the development of manufacturing technology, cold-rolled steel sheets at home and abroad have been 0. Products with a thickness of 05 mm can be used at 100kHz in strong cold, but are expensive.

Classification of conductor

magnets

1.High-frequency conductive

magnets

Because the frequency is up to 500kHz, high-frequency conductive magnets can only be made of powder. Its powder particles are extremely fine and sintered by pressurization, but also heat at high frequency currents.

The former Soviet Union and China as early as the 1950s have produced ferrogen high-frequency conductivity magnets. The disadvantage of burning into ceramic-shaped high-frequency conductor is that it is hard and brittle, which is very difficult to process and affects its use and popularization. Since then, mud-like conductors have been developed, but the magnetic conductivity is low.

Ferring high-frequency conductive magnets, there are a number of magnet factory production, in addition to radio equipment factory production of soft magnet oxygen materials, there is a higher Curi point temperature (500degrees C)and operating frequency (300 to 700MHz).

2.The conductive magnet can be processed

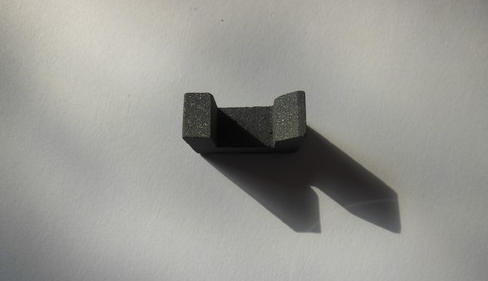

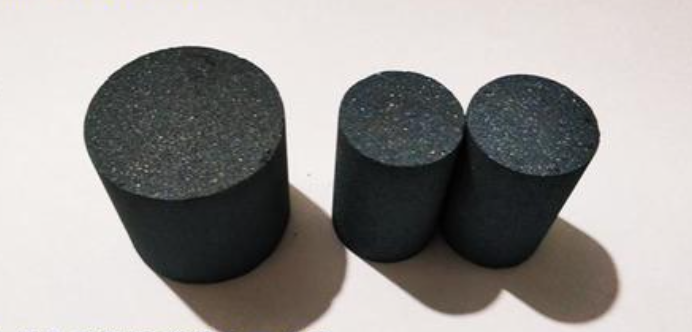

Industrial developed countries have developed processable conductive magnets, the United States, Germany, Japan and other countries have products.

The processable conductive magnets are supplied with cylinders, rectangular strips and plates, and can be machined into the desired shape. Processable conductive magnets are generally manufactured from ferrite, also known as magnetodermes, and are molded and dried by very fine iron powder and adhesive. Iron powder particles are insulated. The higher the frequency of use of the conductor, the finer the iron powder required, and the higher the density of the conductive magnet, the higher the magnetic conductivity. The heat resistance of the conductor depends on the material of the adhesive. It is now recognized that the thermal conductivity of adhesives is also important. Experiments show that the higher the thermal conductivity of the adhesive, the faster the conductive magnet cools down.

The service life of a machineable conductor is related to its temperature of use. Like silicon steel guide magnets, sensors are designed to allow an effective ring to well move the tropical tropics on the conductor.

3.Hand-formed conductive magnets