Passivation one common surface treatment of magnets

We all know that the sintered NdFeB permanent magnet material is

produced by powder metallurgy technology. It is a kind of material with

relatively active chemical properties. There are tiny pores inside, and the

Nd-rich phase is easy to oxidize in the air. After the material is corroded or

damaged by the components, the magnetic properties will be attenuated or even

lost over time, which will affect the performance and life of the whole

machine, so strict anti-corrosion treatment must be carried out before use.

The surface protection of NdFeB permanent magnets has three

aspects:

1-Improve the corrosion resistance of NdFeB, and use various

surface protections to resist corrosion such as humid environments, acids,

alkalis, salts, and harmful gases;

2- Thoroughly clean the surface of the magnet, such as removing

the loose magnetic particles on the surface, to form a smooth surface to

prevent the loose magnetic particles from affecting the function or damaging

the magnetic system;

3-Operation protection, prevent magnetic particles from falling

off during assembly or work.

NdFeB passivation is like phosphating, which is to form a

protective film on the surface of the workpiece through a chemical method on

the neodymium iron boron surface to achieve the purpose of anti-corrosion of

the workpiece. Surface chemical conversion coating technology is a common

method of surface treatment. At present, NdFeB surface chemical conversion

coating treatment mainly uses phosphating technology, mostly ordinary zinc, or

iron phosphating. The phosphating film itself has poor corrosion resistance and

often It does not independently undertake the anti-corrosion effect, but

cooperates with electrophoresis, coating, etc. as the outer layer of composite

anti-corrosion. At the same time, phosphoric acid and phosphate compounds are

used in a large amount in the phosphating process, which is prone to phosphorus

pollution, causing adverse consequences such as eutrophication of water bodies.

The process environment is not friendly. Compared with the phosphating agent,

the passivating agent has simple components, does not contain phosphoric acid

and phosphate compounds, and is more environmentally friendly.

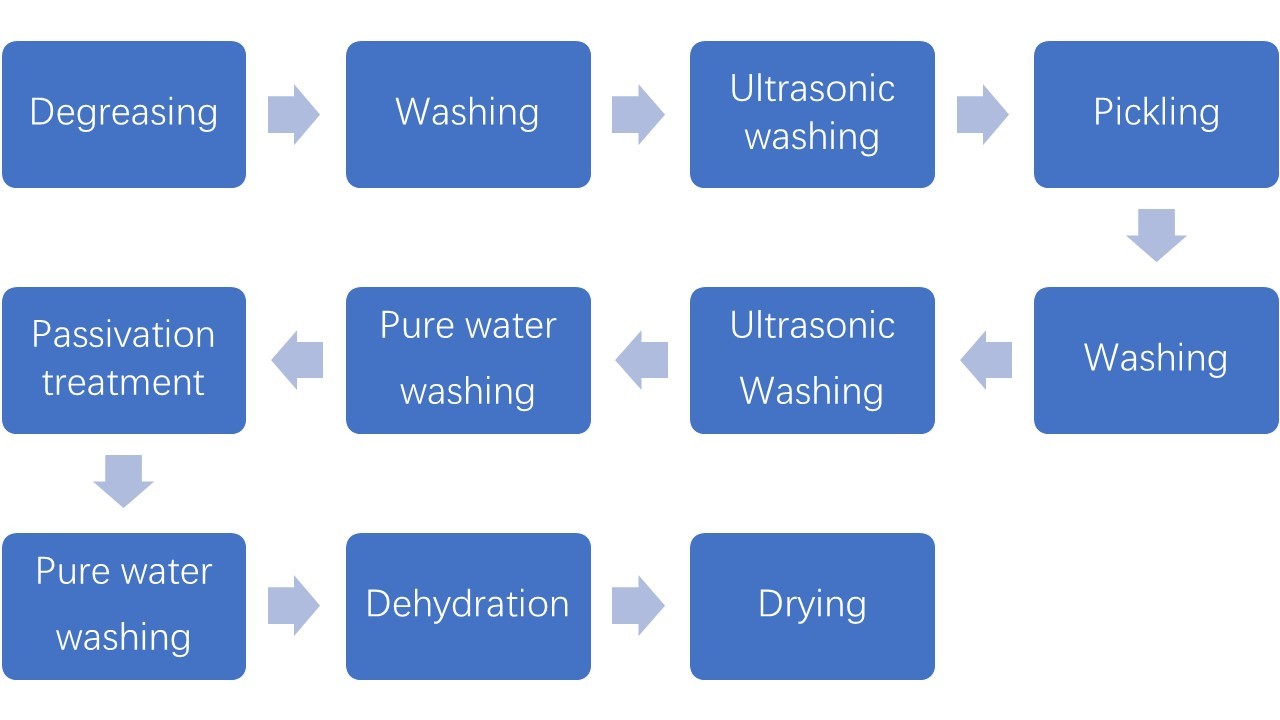

Degreasing

Degreasing can only remove grease, dust, sweat stains and

attached metal shavings on the surface of the NdFeB, but not the rust on the

magnet. The oil stains on the surface of NdFeB are brought from the processing

of materials, such as anti-rust grease used to prevent rust during storage and

transportation, and cutting fluid that parts meet during cutting.

Before further surface treatment of NdFeB, the oil on the

surface must be cleaned, otherwise it will affect the quality of surface

chemical conversion, electroplating or coating. Due to the wide range of

sources and types of oil pollution, the degree of pollution varies greatly, so

the problem of oil removal is very complicated. In order not to cause corrosion

and subsequent residue in the degreasing process, try to use a degreasing agent

with low free alkalinity and total alkalinity.

Pickling

The purpose of pickling is to remove the black ash and rust left

on the surface of the neodymium iron boron. Pickling liquid generally uses

2%~4% nitric acid, and the time is 0.5~2.0 min. Both high acid concentration

and long pickling time are detrimental to the magnet.

Passivation

The passivation treatment method is to place the magnet in a

container containing passivation solution, soak, or spray for a period, or use

the magnet as an anode to pass polarization to achieve passivation, that is, a

passivation film is formed on the surface. As an important surface

anti-corrosion treatment, passivation is commonly used in many metals,

especially metals such as aluminum, zinc, cadmium, tin, and magnesium and their

alloy materials.

Most of the traditional passivation treatments use chromic acid

and chromate as treatment agents, called chromate passivation. The chromate

conversion film formed on the metal surface after treatment has a good

corrosion protection effect on the base metal. . As a separate protective film,

the passivation treatment is simple and practical, and the cost is low. It was

widely used in the early development of NdFeB. But its fatal weakness is that

it contains toxic chromium Cr (Ⅵ),

which is harmful to the human body and the environment, which has prompted

people to actively carry out research on effective alternative technologies. In

recent years, my country has many patents for passivation agents. There is a

passivation agent for neodymium iron boron magnets, including: oxalic acid, surfactants,

and complexing agents. Its composition is simple, and it has the functions of

degreasing, rust removal, and passivation at the same time. Without the use of

phosphoric acid and phosphate compounds, it is a more convenient and

environmentally friendly passivation agent for NdFeB magnets.

In recent years, the corrosion resistance requirements for NdFeB

conversion coatings have become higher and higher, and it is difficult to meet

the requirements by single passivation technology. The commonly used process is

to use composite conversion coating technology, that is, phosphating and then

passivating, by filling phosphorus the pores of the chemical film can

effectively improve the corrosion resistance of the composite conversion film.