DC Motor

The DC motor is a

device that realizes the mutual conversion between DC electric energy and

mechanical energy. According to the purpose, it can be divided into two types:

DC motor and DC generator. Among them, the motor that converts mechanical

energy into DC power is called a DC generator, and the motor that converts DC

power into mechanical energy is called a DC motor (referred to as motor &

motor); DC motors are common power machinery in industries such as mining,

transportation, and construction; The DC motor has a wide range of speed

regulation, smooth stepless speed regulation characteristics, can realize

frequent stepless quick start, braking and reverse rotation; large overload

capacity, can withstand frequent impact loads; can meet the requirements of

various automated production systems This kind of special operation

requirements; because the DC motor has good starting and speed regulation

performance, it is often used in occasions with higher requirements for

starting and speed regulation, such as large reversible rolling mills, mine

hoists, hotel high-speed elevators, planers, Electric locomotives, diesel

locomotives, urban trams, subway trains, electric bicycles, paper and printing

machinery, marine machinery, large precision machine tools and large cranes and

other production machinery. VECTOR can provide DC motors with diameters ranging

from 6mm to 110mm and various flat vibration motors & linear motors, all

complying with CE, REACH, RoHS requirements; products include flat vibration

motors, linear motors, brushed iron core motors, DC brushless motors, Precision

precious metal DC motors, geared motors, etc. Products are widely used in

industrial automation, office automation, automotive electronic equipment,

medical equipment, audio and video equipment, information communication

equipment, aviation models, power tools, massage health equipment, electric

toothbrushes, electric shavers, eyebrow trimmers, hair dryers, portable cameras

, Precision instruments, 3C products and other electric products.

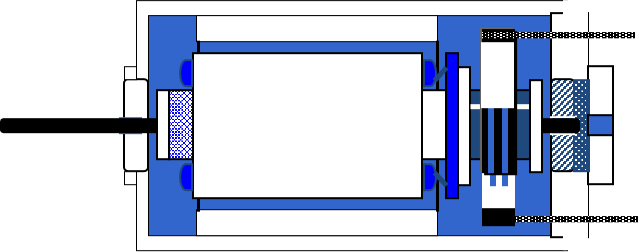

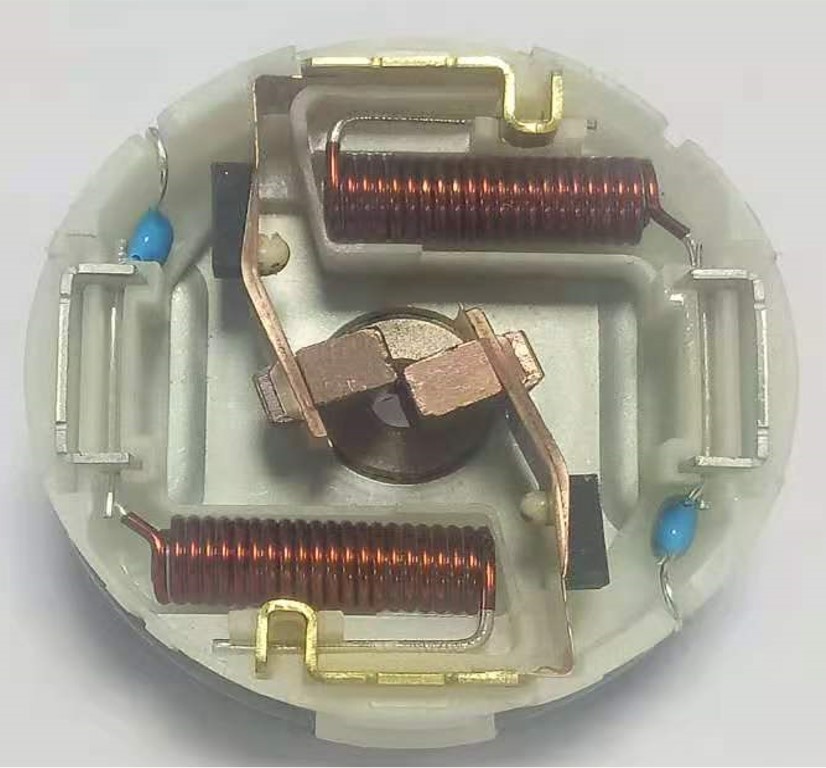

The structure of a brushed DC motor

In recent years,

electric vehicles have gradually gained consumers' affirmation due to their

environmental protection, low cost of use, and preferential purchases. With the

increasing status of electric vehicles in urban transportation, the

corresponding charging stations that need to be configured have gradually increased.

Equipped with an automatic charging system will be the mainstream trend of

charging stations in the future. The charging robot has played a big role in

the charging station, saving a lot of human resources and management costs. It

is truly the smartest, fully automatic, efficient, and affordable charging

solution. There is no doubt that the best choice for the power source required

by the charging robot is the micro motor. The micro motor provided by VECTOR

has high torque, which provides sufficient power while also ensuring the

accuracy of the charging robot. It is an indispensable power support in the era

of intelligent charging.

With the

development of economy, the expansion of cities, the rapid increase of population

and the improvement of quality of life, urban garbage continues to increase,

and garbage disposal has become a major problem at present. The best way to

manage garbage is to split the collection, and this process is tedious and

complicated. The smart trash can came into being. They are generally equipped

with filling sensors to coordinate the digital management of domestic waste

with data management and logistics platforms, making the classification of

waste in modern life cleaner and more effective. Driven by the motor, the smart

trash can cooperates with sensors and data processing to realize the functions

of automatically opening, packing and changing bags. Because the motor we

provide has strong stability and high protection level, it can perform well

even in a relatively harsh working environment.

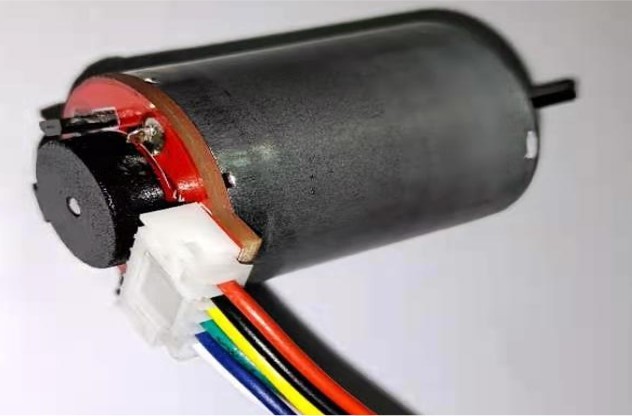

Electronic Parking brake system (EPB) motor

The electronic

parking brake system (EPB) turns the traditional parking lever into a small

button, but it is safer than the traditional lever and will not change the

braking effect due to the driver's strength. The electronic parking brake

system collects data in real time through the acceleration sensor, and after it

is delivered to the computer for calculation, the corresponding force is

increased or eliminated, which realizes the smooth start of the vehicle and

stable parking on the slope. In addition, the system automatically realizes

thermal compensation, ensuring reliable parking in cold weather. A huge braking

effect can be achieved by pressing a small button. The power source is the

micro motor in EPB; the motor cooperates with the control of the computer to

release the brake for the smooth start of the vehicle, and balance the decline

caused by the parking on the slope. It compensates for the temperature

difference between the brake disc and the friction lining; it performs the

braking function efficiently under various driving conditions, which improves

the safety of the electronic parking brake system.