Some introductions of Magnetic gear

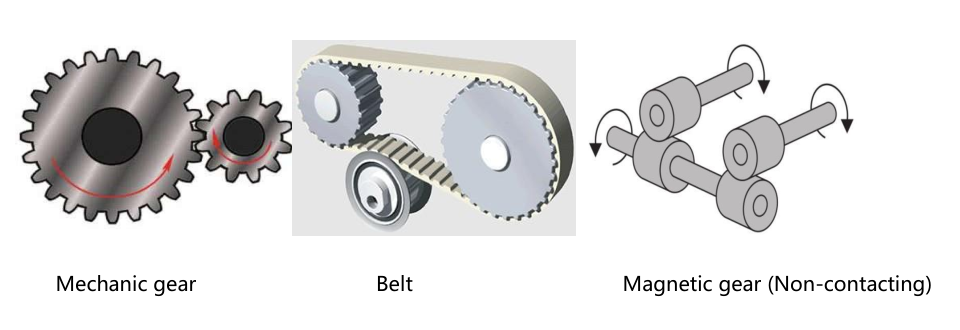

The non-contacting magnetic transmission

drive gear uses the principle of magnetism as transmission, which is a

non-contacting transmission mode. In a clean environment, LCD, PDP, PCB, OLED,

SOLAR CELL and other production lines that do not allow fine impurities to

drive products in a non-contacting state, which solves the problem of clean

environment transmission devices such as gears or belts that generate dust due

to contact work. Vibration, noise. Load protection function; solves the problem

of no damage even if abnormal load occurs. The non-contacting magnetic

transmission wheel has no wear and tear, basically no maintenance, and the

mechanical design is simpler. It is the best choice for a new generation of

transmission

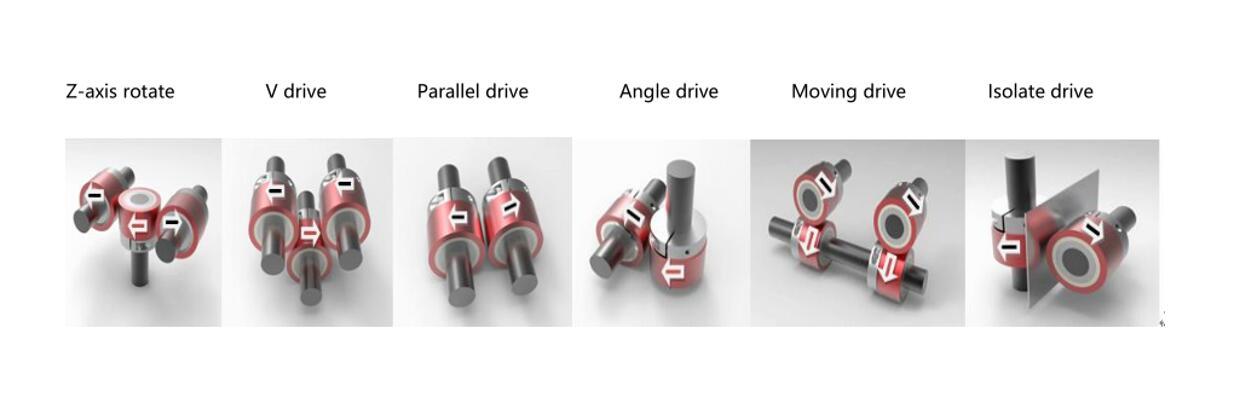

Transmission type

Advantage of Magnetic gear

1. Ultra low dust environment

Magnetic gear with non-contacting condition

transit the product by magnetic torque will not

caused dust in the environment

2. Ultra low noise

Very low acoustic noise and vibration due

to non-contacting between magnetic gear

3. Precise peak torque transmission

As non-contacting between magnetic gear,

two magnetic gears will rotate and make same

magnetic torque as designed for transmit

the product.

3. Low cost

Reduced the cost of maintenance and

improved reliability, lubrication free, longer life.

Application type