Current Development and Application of domestic axial flux motors

The current development and application of domestic axial flux

motors

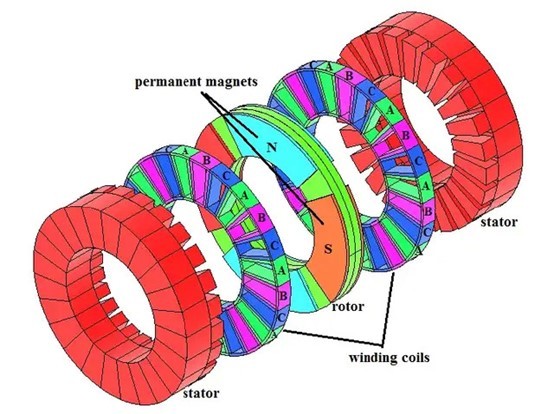

The axial flux permanent magnet synchronous motor has an axial

flux direction, which determines its structure is different from the ordinary

radial motor. Under the same external dimensions, the core advantage of the

axial flux motor lies in the rotor with a larger diameter, it rotates along the

stator rather than inside it. Torque equals force times radius, and an axial

flux motor can get more torque for the same force. This means that the axial

flux motor can output more torque for the same volume of permanent magnets and

copper winding material.

Axial flux motors offer a 30% torque density advantage over

conventional radial motors.

Axial flux motors have many advantages, such as small size, low

noise, high power density, and excellent heat dissipation performance.

It can be seen from the structure diagram that, different from

the radial flux motor, the stator and rotor of the axial flux motor attract

each other and generate an axial force. We all know that the metal is not

resistant to compression, and the axial force is the most feared by the motor.

Lightly, it will increase friction and aggravate vibration. Therefore, the

axial flux motor generally adopts the design of double stators on both sides

and a single rotor in the middle. There are also schemes such as single stator

double rotor and multi-disk type to offset the axial force. Secondly, the gap

between the stator and the rotor is called the air gap, which is an

indispensable part of the magnetic circuit of the motor. The axial flux rotor

is laid flat on top of the stator, and the air gap area is significantly

larger. Its surface flatness and gap uniformity are extremely demanding.

This means that the requirements for machining and manufacturing

accuracy and assembly accuracy are very high, which brings extremely high

manufacturing costs and extremely low production flexibility.

The high manufacturing difficulty also leads to the insufficient

production scale of the axial flux motor, the small market capacity, and the

inability to keep up with the matching parts. Not only the axial flux motor

itself, but also after connecting the drive shaft, the axial movement generated

by the rear end load will also seriously affect the magnetic balance between

the rotor and the stator of the axial flux motor. Once the critical point is

exceeded, the rotor will be adsorbed to the stator. up, it would be a disaster.

These drawbacks in turn lead to difficulties in the application

of axial flux motors, resulting in fewer practitioners in this field, low

product maturity, and lack of R&D verification systems. Under the cycle, it

is difficult to compete with ordinary radial flux motors.

At present, what is the development of the disc motor in China?

What special scenarios are disc motors suitable for?

At present, the mainstream motors in automobiles and

construction machinery in China are still mainly permanent magnet radial

motors, which mainly rely on its high speed and through the high gear ratio

gearbox to achieve the process of reducing speed and increasing torque. Most of

them have a long cylindrical shape with a small diameter and a large axial

dimension. The axial flux motor is just the opposite. Because of its

disc-shaped structure, the magnetic field action area is enlarged, which makes

the power generation efficiency higher. Most of them have the characteristics

of large diameter and thin axial size.

From the current point of view, the development of axial flux

motors in China has shown a multi-point blooming situation. There are many

enterprises engaged in the development of axial flux motors in Jiangsu,

Zhejiang, Shanghai and Beijing. Compared with the private customization of YASA

and Magnax in foreign countries, most domestic enterprises aim at mass

production, optimize the material and structure of the motor, and sacrifice a

certain power density to achieve a motor that meets market demand and is

reasonably priced. level.

From the perspective of the application scenarios of disc

motors, it can be subdivided into the field of elevators, commercial vehicles

and buses, construction machinery, generator sets, range extenders, military

and aerospace fields, etc.

1. Elevator field. KONE Elevator, with its own developed disc motor traction machine (also a disc motor), once stood on the commanding heights of the elevator industry. Relying on its flattening advantage, the traction machine is placed between the elevator car and the shaft wall, eliminating the traditional traction machine room, also called a machine room-less elevator.

2. Commercial vehicles and buses. The P2 motor of the commercial

vehicle (the motor is placed between the engine and the gearbox) can perform

power transmission during rapid acceleration and energy recovery during

braking. This directly reduces fuel consumption and is also in line with the

implementation of current environmental protection policies. The use of the

disc motor effectively solves the problem of excessive axial size of the engine

+ motor + gearbox, which plays a good role in the layout of the interior space.

Similarly, the wheel-side motor of the pure electric bus is also a model with a

low floor and a wide aisle due to the thin axial size of the disc motor.

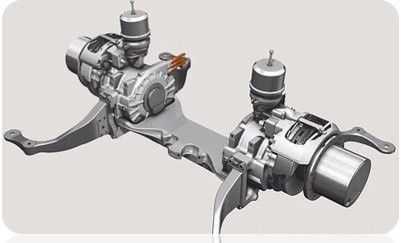

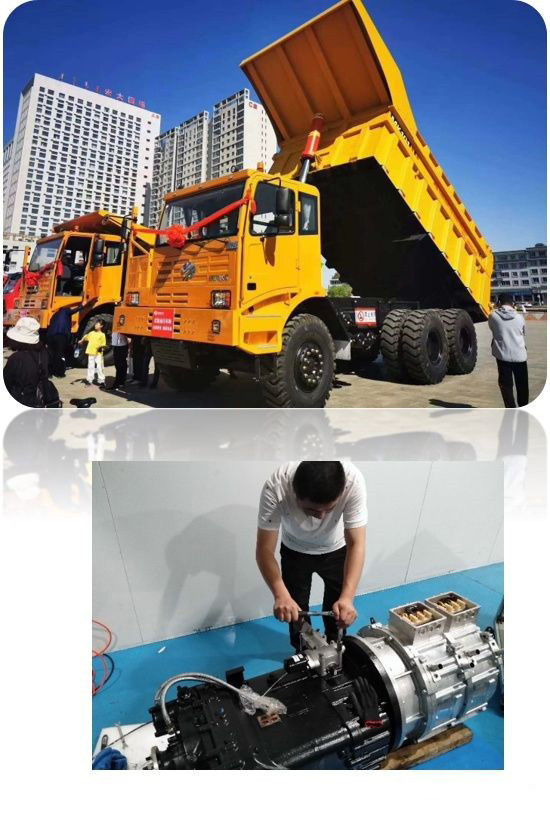

3. Construction machinery and off-road vehicles. In loaders,

forklifts, industrial ceiling fans, mining trucks, sweepers, etc., it is mostly

used in lifting motors, travel motors, fan motors, and main drive motors. With

its thin thickness, high power density and low rotational speed, customers'

solutions can be optimized.

4. Range extender, generator set field. At present, the program

extension market is very hot, which is also related to its high cruising range

and low fuel consumption. Many related passenger cars and commercial vehicles,

as well as unmanned field vehicles, have developed extended-range products. The

comprehensive fuel consumption will save about 30% of fuel consumption compared

with fuel vehicles. In the field of generator sets, the disc motor can be said to

subvert the traditional generator set. The air-cooled asynchronous machine is

replaced by a disc permanent magnet motor, which greatly reduces the size and

weight of the generator set, and also greatly improves the power generation

efficiency. Widely used in generator sets between 1-100kw.

5. Military and aerospace products. Relying on the high-power

density of the disc motor, it has been well used in pure electric aircraft, and

can even achieve a natural air-cooled structure! In the field of military

industry, it is more used in battlefield in-wheel vehicles. The in-wheel motor

makes the vehicle more comfortable with its excellent steering ability and

narrow space layout.