Magnetic Drive Pumps: A Comprehensive Guide

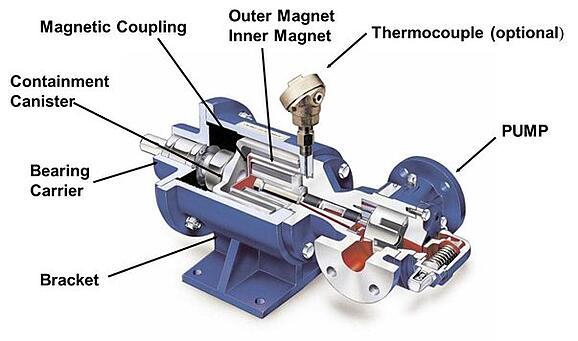

1.Structural

Characteristics

Magnetic

pumps consist of three main components: the pump, the magnetic coupling, and the drive motor.

· Pump:

The pump is typically constructed from corrosion-resistant, high-strength

engineering plastics, corundum ceramics, or stainless steel, ensuring protection against corrosion and preventing contamination of the transported medium.

· Magnetic

Coupling: Magnetic couplings are essential components for non-contact torque transmission, enabling leak-free operation.

They typically come in two forms: disc-shaped and cylindrical-shaped.

Cylindrical couplings are more widely used due to their ability to handle

higher axial forces.

· Motor:

Magnetic pumps generally employ standard motors, with specific requirements considered based on regulations.

2.Use and

Maintenance

2.1 Precautions for Using Magnetic Pumps

· Verify the smooth rotation of the coupling by hand after installation.

· Install a filter at the inlet with a filtering area three to four times the

cross-sectional area of the pipeline to prevent debris from entering the pump.

· Strictly prohibit idling operations.

· For

high-lift magnetic pumps, install a check valve on the outlet pipeline to

prevent water hammer damage during sudden shutdowns.

2.1.1 Pump Opening Procedure

1. Open the inlet valve and fill the pump with the liquid to be transported before starting the motor.

2. Close the outlet valve.

3. Jog the electric motor to check the correct direction of the magnetic pump.

4. Once the magnetic pump starts, slowly open the outlet valve.

5. Allow the pump to reach normal operating status before adjusting the outlet valve to the desired opening.

6. Conduct a test run for 5-10 minutes. If no abnormalities are observed, proceed with normal operation.

2.1.2 Shutdown Procedures

1. Close the outlet valve.

2. Cut off the power supply.

3. Close the inlet valve.

4. Clean the flow channel in the pump and cut off the power supply when not in use for an extended period.

2.2 Maintenance Precautions

· Pump Shaft Breakage: The primary cause of pump shaft breakage is dry running, leading to bearing dry grinding and shaft twisting. Regularly check the water level to prevent dry running.

· Bearing Damage: Bearing damage can result from water interruption or impurities in the pump. Additionally, misalignment between the inner and outer magnetic rotors can affect earing life.

· Inability to Pump Liquid: Reasons for this failure include air leakage in the suction pipe, insufficient liquid in the pump, debris blockage, pump reversal, or excessive suction height. Check and address these potential issues before disassembling the pump.

2.3 Additional Considerations

· Magnetic Coupling Maintenance: Pay attention to the proper operation of the magnetic coupling. Excessive heat generation can affect its performance. Ensure adequate cooling to prevent demagnetization and coupling failure.

· Speed Verification: When assessing speed sufficiency, first confirm the motor's speed using a tachometer. If the motor speed is normal, consider potential magnetic coupling slippage.

· Troubleshooting

Insufficient Lift and Flow: Address air in the medium, impeller damage, insufficient speed, excessive lift, or debris blockage in the piping to rectify these issues.

3. Conclusion

Magnetic drive pumps offer a reliable and leak-free solution for various applications.

Their versatility, efficiency, and ease of maintenance make them a preferred choice in various industries. By understanding their structural characteristics, proper operation, and maintenance practices, users can maximize the performance and longevity of these pumps.