Home / Magnetic drive Pump

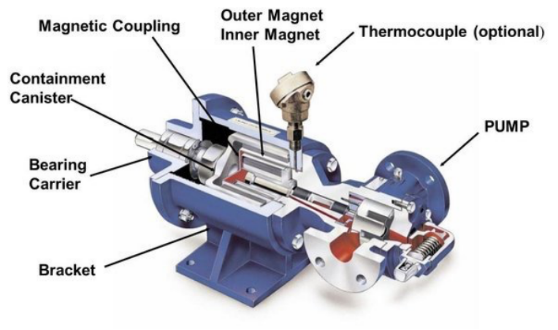

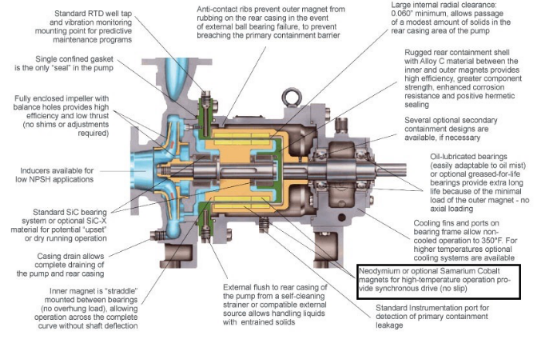

Magnetic drive pumps, or magnetically coupled pumps, vary from the traditional pumping style, as the motor is coupled to the pump by magnetic means rather than by a direct mechanical shaft. The pump works via a drive magnet, driving the pump rotor, which is magnetically coupled to the primary shaft driven by the motor. They are often used where leakage of the fluid pumped poses a great risk (e.g., aggressive fluid in the chemical or nuclear industry, or electric shock - garden fountains). They have no direct connection between the motor shaft and the impeller, so no gland is needed. There is no risk of leakage, unless the casing is broken.

Since the pump shaft is not supported by bearings outside the pump's housing, support inside the pump is provided by bushings. The pump size of a magnetic drive pumps can go from few Watts power to a giant 1MW.

Characteristics (magnetic application):

Generally high Hc (coercive force) NdFeB magnets SH, UH, EH grades or high Hc (coercive force) SmCo magnets are used in magnetic pumps, mostly in block or arc shapes.

Appearance (strict control chip, break, crack, etc), parallelism and perpendicularity are key features for magnetic drive pumps, meanwhile, magnetic property consistency (Br, Hc, Hk) needs to be highlighted in manufacturing, which is critical control point.

Testing:

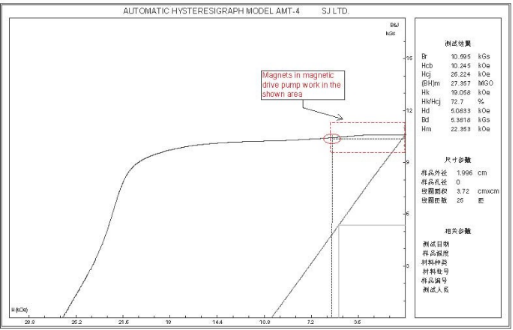

Magnetic property:

A.Demagnetization curves in room temperature and designated high temperature

Supporting Equipment: Hysteresisgraph

Applicable magnet types: NdFeB, SmCo

B.Irreversible demagnetization by comparing

1.Magnetic flux in room temperature

2.Magnetic flux after magnets are heated in elevated temperature

Supporting Equipment: flux meter, industrial oven

Applicable magnet types: NdFeB, SmCo

Appearance and dimensions

A.Appearance:

1.Salt Spray Test: set in certain humidity, PH based on application

2.Press Cook Test: set in air pressure, temperature and humidity based on application.

3.Plating/Coating thickness; using x-ray-fluorescence to analyze the thickness of surface plating/coating.

Supporting Equipment: SST Cabinet; PCT cabinet; XRF analyzer,

Applicable magnet types: NdFeB, SmCo

B.Dimensions:

1.Geometric tolerances (e.g. parallelism, perpendicularity, etc)

2.Desired size and shape

Supporting Equipment: micrometer, caliper, image measurement tool,

Applicable magnet types: NdFeB, SmCo