FeCrCo Magnets

| Categories | FeCrCo Magnet |

|---|---|

| Brand | Vector Magnets |

| Update Time | Apr 19,2025 |

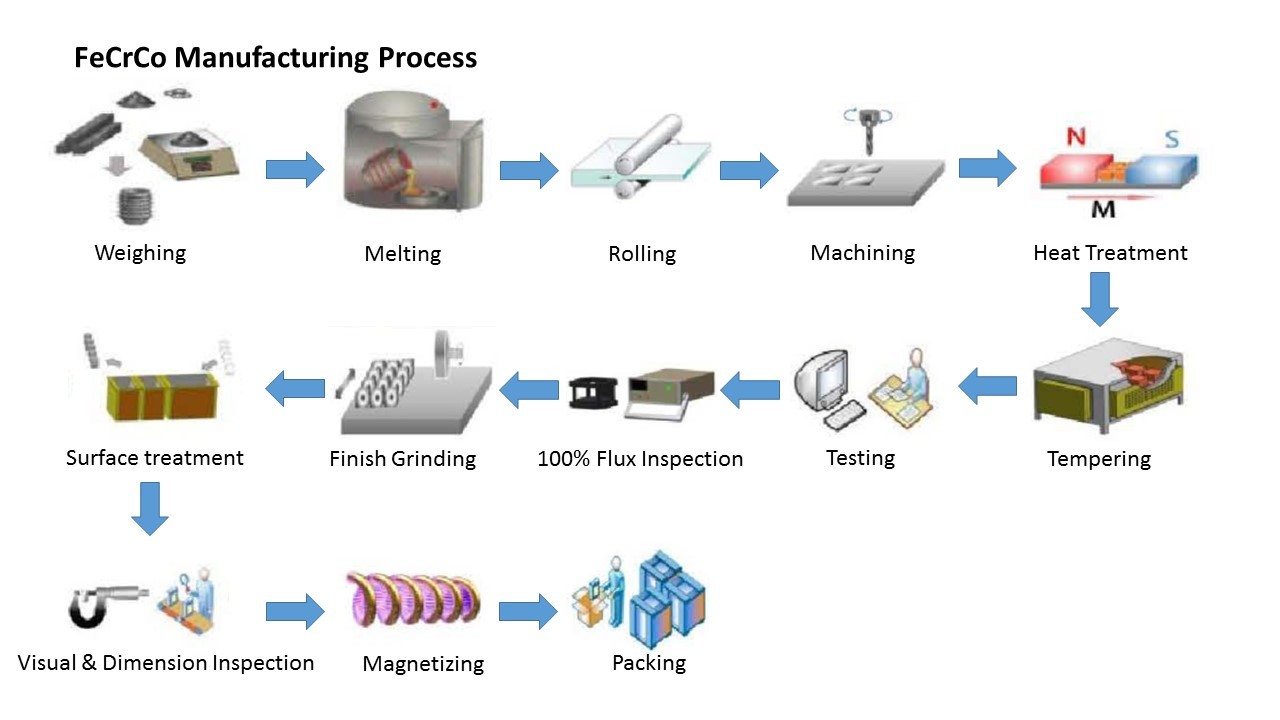

FeCrCo magnets, a new type has come into the world in the 1970's. These magnets' properties are featured with higher permanent magnetic property, comparable to those of cast AI-NI-Co magnets, and with a good ductility in the as-quenched state, but with Co content 50% smaller than AlNiCo magnet.

Being a type of machinable permanent magnetic alloy, FeCrCo is also famous for its great plasticity, ductility and machinability, this performance is far better than casting permanent magnetic alloys, while its high working temperature outclasses that of NdFeB permanent magnet. They can be made into semi-hard magnetic alloy, especially suitable for making the small and thin elements with accurate dimensions and complicated shapes, such as wire, tube, bar, strip, etc., with strip as thin as 0.05mm, wire products as thin as 0.1mm, if mechanically processed by filing, milling, digging, drilling and punching.

Iron chromium Cobalt (FeCrCo) magnets are similar to Alnico magnets in magnetic property, but they have better mechanical property. FeCrCo alloys can be easily hot deformed and machined. There are practically no limitations of their shapes and sizes. They can be made to block, square rods, round rods, tube, strips, wire. FeCrCo magnets are beneficial combination of magnets and mechanical properties. Their maximum working temperature can be as high as 400°C.

FeCrCo Can be made to small and complex shape components. Its minimum diameter can reach 0.05mm and the thinnest thickness can reach 0.1mm, so it is suitable for the production of high-precision components. It has good temperature stability and corrosion resistance. The high Curie temperature is about 680℃ and the highest working temperature can reach 400℃.

Iron-Chrome-Cobalt permanent magnets are a malleable, magnetically semi-hard alloy which is available in cast form (see the Alnico Magnet section) and as thin rolled strip, bar, rod or wire from Rolled Products facility. It is an excellent material for hysteresis coupling and for sensor applications. It is also a substitute for CuNiFe, which is no longer commercially available.

Pros:

1. Multiple-pole availability, goodmachinability(share the hardness with 304 stainless steel), specifically fitsdesigns of high precision, complexed shape and small sizes, say, thin sheets

2. Tc (Curie temperature) as high as680℃

3. Tw (Working temperature) as high as400℃

4. Low reversible temperature coefficient

Cons:

1. Not very high magnetic performance

2. Maximum Br (Residual induction)ranges from 13000 Gs to 14000 Gs

3. Maximum Hc (Coercive force) isaround 650 Oe (52kA/m)

4. Maximum (BH)max (Maximum energyproduct) is around 6.0MOGe

FeCrCo alloys, with outstanding magnetism and plasticity, are widely used in electro-acoustical, electronic industry, telephone, tachometer, micro-motor, loudspeaker, micro-rely-swith, nautical instrument, space aviation instruments, automobile meters, automatic controlling meter, compass, oil exploration, hydraulic locate gauge, computer-embroider machine, signal produce system, guard against theft, relay counter, hearing aid, magnetic medical treatment, family appliances,etc. All our supplied are strictly according to National standard, being examined by professional inspectors.

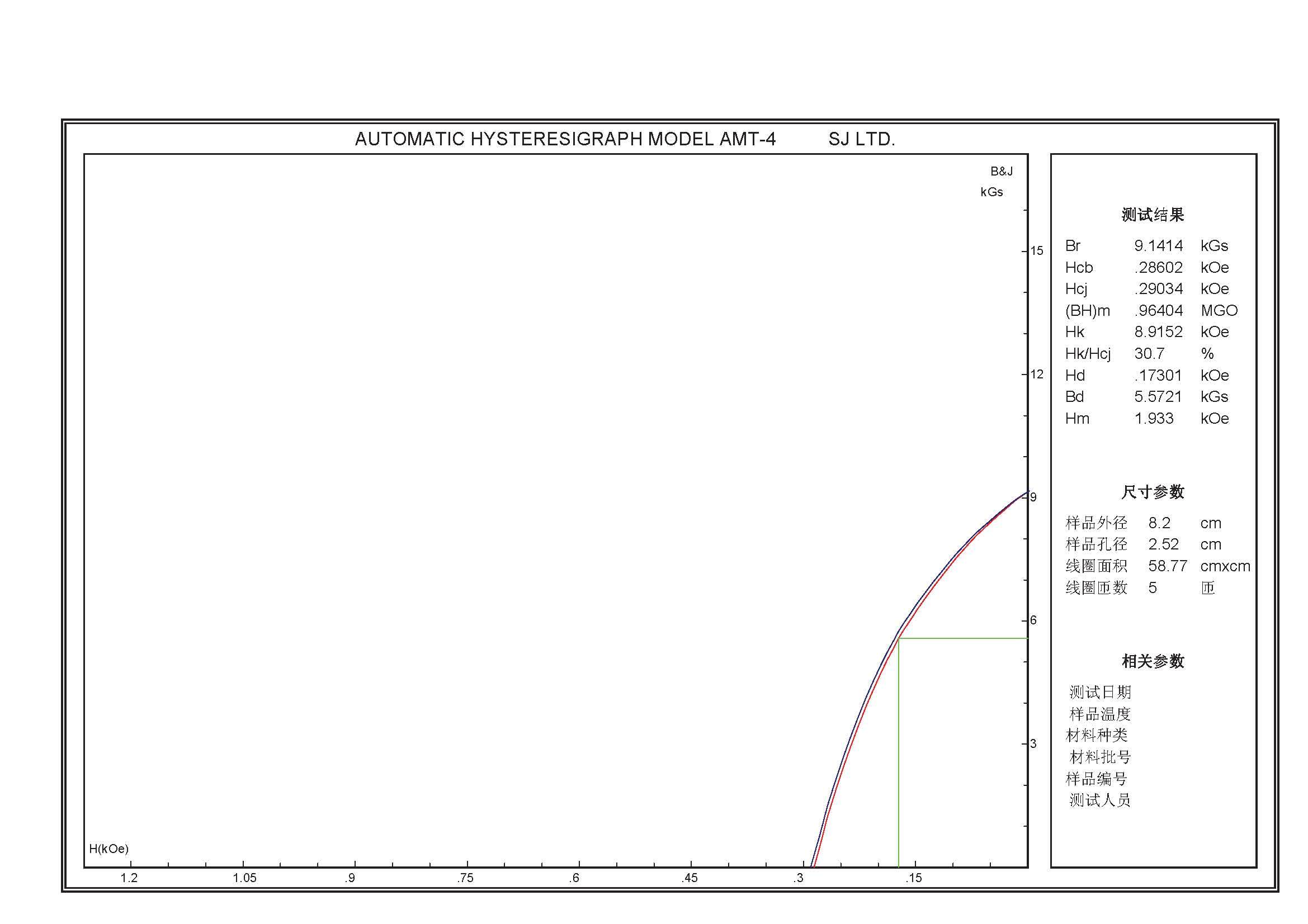

FeCrCo Ferrite Demagnetisation Curve

- Loading...

- Name

- Tel

- *Title

- *Content